Products

スパイラル

リテイニングリング

特長 Feature

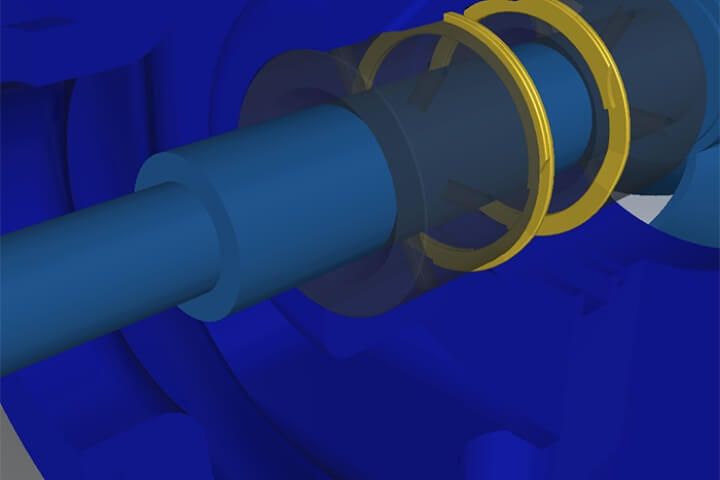

スパイラルリテイニングリングの脱着

リングを組み付ける際は、特別な工具を使うことなく、手組が可能です。また、作業効率を上げるため専用治具を使用することも可能です。取り外しの際はノッチにマイナスドライバーなどの先端をかけて、溝からリングの端を引き上げて外してください。

詳細を見る腐食に強く、磁性が低いSUS316製スパイラルリテイニングリング

腐食が懸念される環境下で止め輪を使用する際、ステンレスを選択する場合が多いですが、JIS規格では大方がSUS304です。しかし長時間水分に触れる状態や、塩分濃度が高い環境下で使用すると、SUS304では腐食が進行し、止め輪の機能が損なわれる恐れがあります。 そ の様な劣悪な環境下でも、止め輪の機能が損なわれないよう当社ではSUS316を用意しております。SUS316はSUS304にMoを添加することにより、緻密な不動態皮膜が形成され、優れた耐食性を発揮します。高い耐食性を要求されるポンプのメカニカルシールや締結部品などに当社のSUS316製スパイラルリテイニングリングが採用され、高い評価をいただいております。

またSUS316は他のステンレス鋼に比較して、各種溶液への耐食性も優れています。オーステナイト系ステンレス鋼は面心立方晶構造であり、溶液化処理状態では非磁性ですが、冷間加工を加えると磁性が発生します。これはオーステナイト組織の一部が加工誘起マルテンサイト系に変態するためです。よって強度を上げるために、伸延、圧延をしたり、止め輪を成形するなど塑性加工をすると、弱帯磁性となり磁石反応を示します。鋼による組織変態の度合は含有元素の多少に影響されます。ステンレス鋼の代表種であるSUS304では、Ni量に応じてマルテンサイト変態が生じやすく透磁性が大きくなるため、顕著な磁石反応を示しますが、SUS316はマルテンサイトに変態しにくく冷間加工の影響をあまり受けません。従って弱電機器などで非磁性の止め輪が必要とされる場合は、SUS316製スパイラルリテイニングリングの採用をご検討ください。

ラインナップ Lineup

オーダーメイドの他、当社オリジナルの標準品を取り揃えております。

中荷重用リング

2巻きのリングで、軽荷重用リングのおよそ2倍のスラスト荷重に耐えることができます。

重荷重用リング

ローターシャフト用プレインベアリングの固定用に使用されています。狭いスペースでの組付けの優位性により採用されました。過酷な環境下での信頼性も評価されています。

穴用/FRRNシリーズ

軸用/FRSNシリーズ

使用例 Use Case

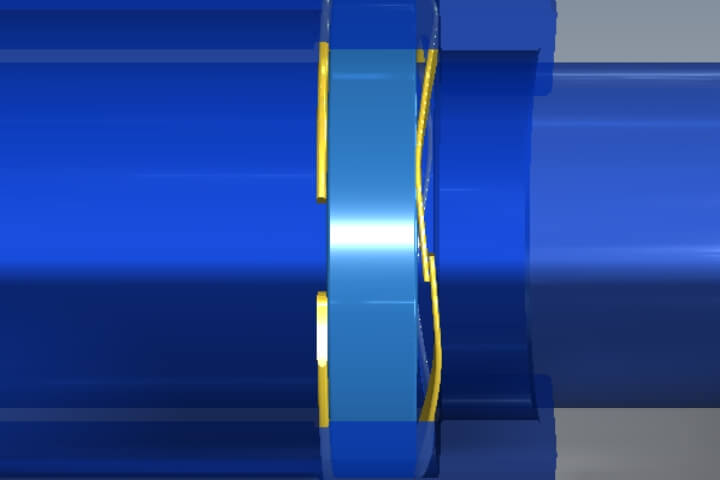

プレインベアリング固定

ローターシャフト用プレインベアリングの固定用に使用されています。狭いスペースでの組付けの優位性により採用されました。過酷な環境下での信頼性も評価されています。

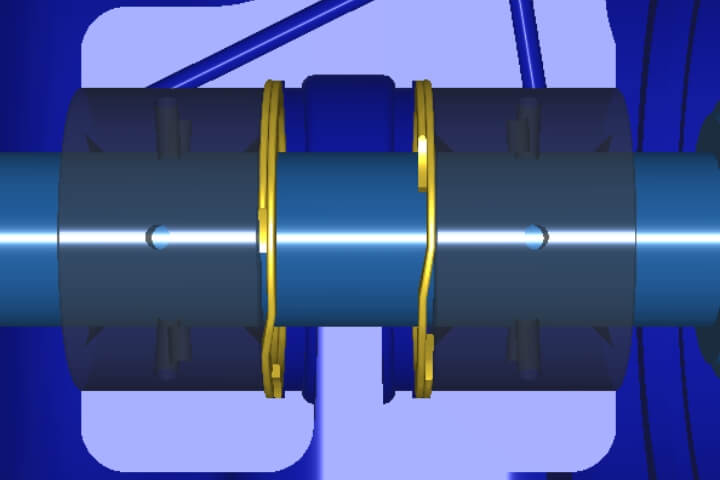

転がり軸受け固定

軸受けを止め輪で固定する際は、同時にプリロードスプリングで与圧を加えることにより、振動による損傷などを未然に防ぐことができます。