製品案内 Product

スプリング

(コイルドウェーブ

スプリング)

リテイニングリング

よくあるご質問 FAQ

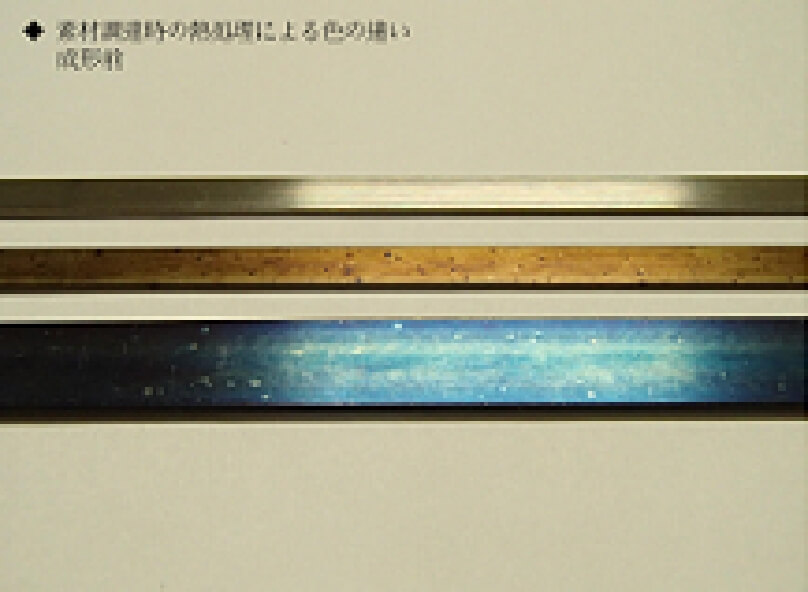

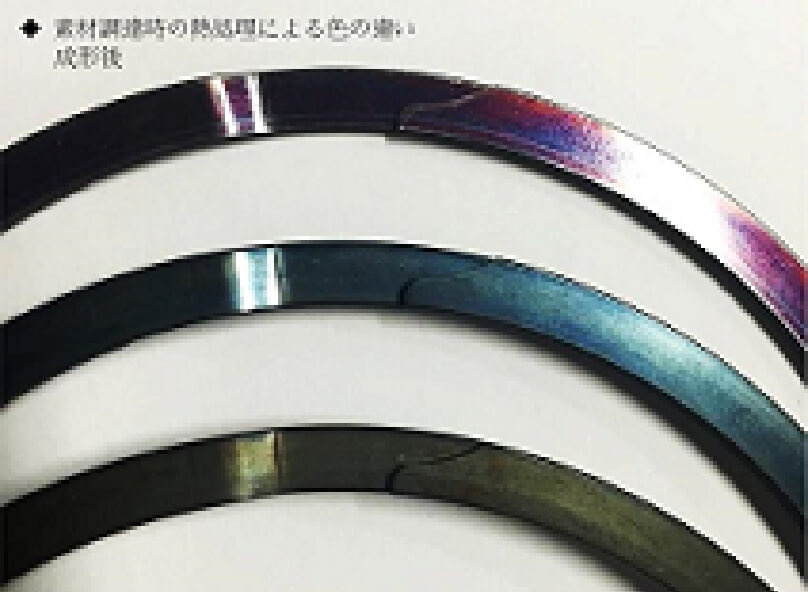

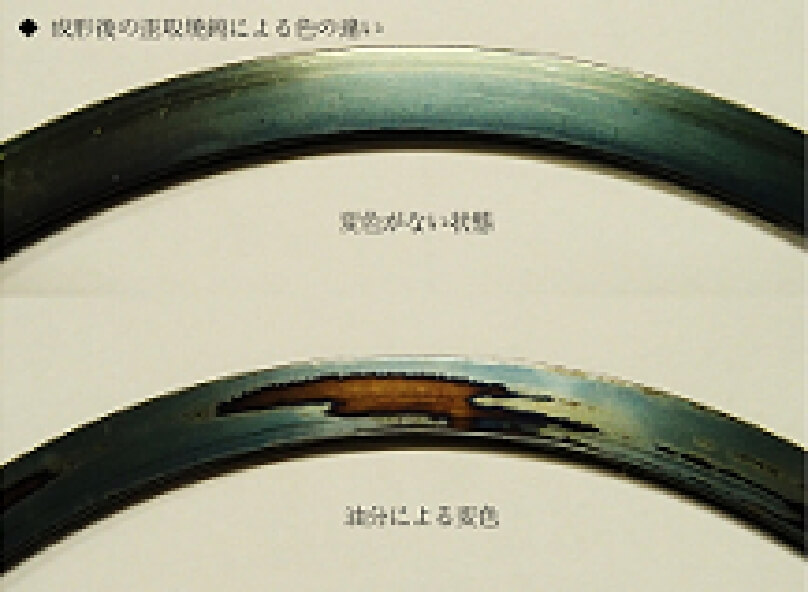

弊社では予め熱処理された素材をメーカーから調達し、それを弊社で成形します。この際、調達した段階で既に色が異なっている場合があります。(写真左・中参照)この色違いが製品の機械的特性に影響を及ぼすことはございません。

また、必要に応じて弊社でも歪取り焼鈍という熱処理をおこないますが、その過程で色の違いが発生することがあります。(写真右参照)この原因は、素材に付着している油分の状態や、熱処理炉内の微細な雰囲気の違いにより、製品表面の酸化被膜の色違いとして表れてしまいます。この酸化被膜の色違いも製品の機械的特性に影響を及ぼすことはございません。

SUS304などのオーステナイト系ステンレスは溶体化処理状態では磁石に付きませんが、冷間加工を加えると磁石に付くことがあります。これはオーステナイト組織の一部がマルテンサイト組織に変態するためです。依って止め輪やばねを成形するなど、塑性加工をすると弱帯磁性となり磁石反応を示します。

磁性を嫌う場合は脱磁処理を行ったり、マルテンサイト変態しにくいSUS316の使用をお勧めします。

弊社製品の挿入治具は、相手物の先端から溝までの長さなどの条件により、形状が変わりますので、標準的な挿入治具はございません。専用に設計しますのでご相談ください。

※溝が、穴や軸の先端から近ければ手で組み付けることができます。

脱着方法につきましてはこちらのPDFファイルをご覧ください。

●スパイラルリテイニングリング製作実績

最大:外径φ740mm 最小:内径φ5.6mm

●スクロウェーブスプリング製作実績

最大:外径φ500mm 最小:内径φ5.6mm

これ以外でもご要望があれば検討いたしますのでお問い合わせください。

お問い合わせ用紙又はお問い合わせフォームにご要望事項を記入の上、お問い合わせください。

設計製作の可否をご回答いたします。